There are many power plants and heating plants in Europe that use a kind of GREEN fuel which is shipped from South Africa. And this green fuel is known as wood pellets.

Wood pellet production plant started to run in South Africa almost 10 years ago, but it still hasn’t formed the scale of mass application of wood pellets. Although it might be difficult to run large power plants with wood pellets, it is much possible to develop small power plants to use wood or other biomass pellets. What’s more, local hospitals, factories, large housing estates, villages or towns can also adopt wood pellets as the source of heat.

Wood pellets perform extremely well in producing combined heat and power and they save 40% cost in producing hot water, steam and hot compared to other fuels such as coal or electricity. So South Africa is most probably to develop its local wood pellets market in a few years. It is also promising to establish more wood pellet production plants to produce wood pellets and export to Europe, so as to make more profit.

What influences the establishment of wood pellet production plants?

- The most important might be an easy access to raw materials. This not only means the low cost of purchasing raw wood chips or sawdust, but also means the low transportation cost.

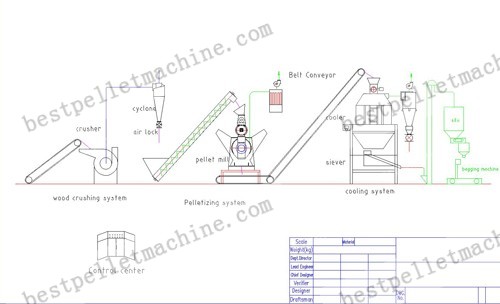

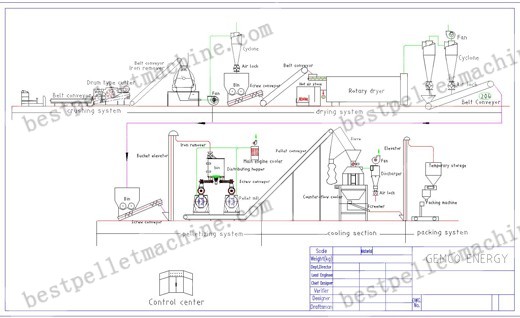

- Secondly the production cost, that means, the cost of factory, power as well as equipments. Buying those European/American made wood pellet production machines are indeed very well, but they occupy great amount of capital. On the contrary, pellet machines made by China, especially GEMCO (the world famous pellet machine manufacturer), are both low in price and good in performance.

- Lastly, consider labor cost.