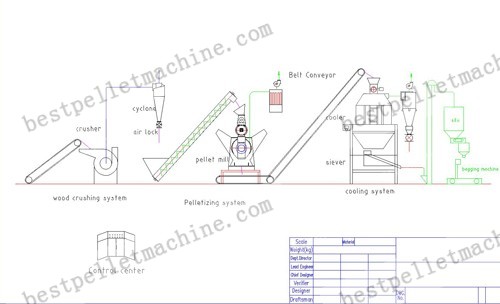

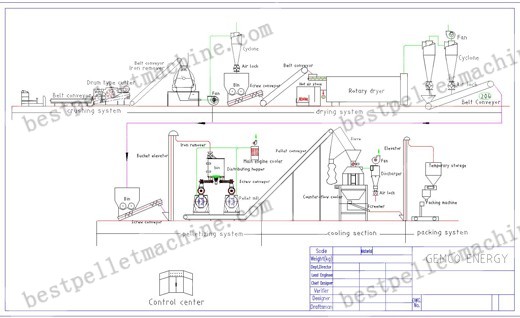

Nowadays, many companies in different countries are interested in setting up complete pellet production line for wood and other biomasses. Some are familiar with this field, but some others do not have much knowledge about it. Here we’d like to explain the composition of a complete biomass pellet line. Take raw material wood as example.

The composition of complete wood pellet line

* Wood crusher: if your raw material is wood chips, wood logs or tree branches, they should be crushed first to become small size 3-5mm diameter sawdust, so that they are suitable for pelletizing.

* Wood crusher: if your raw material is wood chips, wood logs or tree branches, they should be crushed first to become small size 3-5mm diameter sawdust, so that they are suitable for pelletizing.

* Conveyor: for large complete pellet line, the crushed sawdust should be conveyed by screw conveyor or other kinds of conveyor to the sawdust dryer.

* Dryer: it is used to dry the wet sawdust to certain moisture content. Usually the required pelletizing moisture content is around 8-18%. Either too dry or too wet will cause low forming rate of pellets.

* Dryer: it is used to dry the wet sawdust to certain moisture content. Usually the required pelletizing moisture content is around 8-18%. Either too dry or too wet will cause low forming rate of pellets.

* Elevator: the bucket elevator or screw elevator is adopted depending on the actual use. The aim is to feed the pellet mill evenly.

* Pellet mill: both small flat die pellet mill and large ring die pellet mill can be chosen according to your capacity requirement. This is also the most important part in a complete wood pellet line. While what determines the pellets density and quality is the pellet mill die.

* Pellet mill: both small flat die pellet mill and large ring die pellet mill can be chosen according to your capacity requirement. This is also the most important part in a complete wood pellet line. While what determines the pellets density and quality is the pellet mill die.

* Pellet cooler: after produced by the pellet mill, wood pellets go to the cooler for cooling and sieving (to get rid of those broken ones).

* Pellet cooler: after produced by the pellet mill, wood pellets go to the cooler for cooling and sieving (to get rid of those broken ones).

* Pellet packing machine: this is also important for those who make wood pellets for sale. The packing machine can weigh the pellets and seal the bags.

Complete pellet lines have been built all over the world to help people gradually replace coal or other fuel resources which is bad to the environment. And more people tend to choose wood pellets as their fuel source. So it is wise to set up a complete wood pellet line.